PP Pleated Filter Cartridges

Advantages:

Designed for general filtration purposes of both liquid & gas.

Filtering material is double layered polypropylene membrane and internal support is given by PP shell.

Thermally welded without any adhesive or medium break off.

Excellent chemical compatibility, high flow rate, low pressure difference, long life, low price, wide filtration.

Precise and can be used in different place.

Resist to sanitization of high pressure and steam.

Excellent dirt holding capacity.

Quality Assurance:

ISO 9001:2000 certified company.

Pharmaceutical grade material.

Pharmaceutical grade workshops, (according to GMP criterion).

Strick test before packing.

Applications:

Medical Industries : Filtration of organic solvent and compressed air and other gases.

Electronic Industry : Pre-filtration in returning water filtration system.

Food & Beverage Industries : Filtration of wine, mineral water and purified water.

Others : Liquid filtration of organic solvent, ink, galvanization fluid, metal cutting fluid and sensitization anticorrosion fluid etc.

Materials Of Construction:

Membrane : PP.

Core : Polypropylene.

O-ring/Gasket: Silicone/Viton/TEF/EPDM.

Technical Data :

Filtration efficiency up to 98%

Effective filtration area (10"): >0.6 M2

Normal working temperature: <55°C/131°F

Max. working temperature : 8o°C (P<1 bar)

Max. differential pressure : 4.2 bar.

PH value : 1-13.

Sterilization method : Autoclaving (121+2°C) within 30 min.

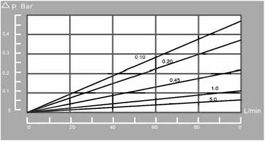

Water flow rate with : See the chart, different pressure

Specifications:

Pore size(µm): 0.10, 0.20, 0.45, 1.0, 3.0, 5.0, 10, 20, 40.

Outer Diameter(mm): 68.

Length (inch): 5, 10, 20, 30, 40.

Endcaps: DOE, SOE(code2,code3,code7,code8)