PTFE Pleated Filter Cartridges

PTFE Absolute rated membrane cartridges are highly retentive hydrophobic or hydrophilic membrane filters that have been specially designed for critical applications. The PTFE membrane Cartridge in an all-propylene construction provides excellent chemical compatibility and superior flow per surface area as compared to other membrane cartridges. PTFE cartridge is ideally suited for aggressive chemicals such as acids, bases & solvents. It gives superior flow & pressure drop characteristics for gas filtration & tank venting applications. Are 100 % integrity tested with good particle removal efficiency at 0.1 & 0.2 microns.

FEATURES & BENEFITS:

Hydrophobic PTFE membrane, prevents moisture in venting and wet air filtration.

PTFE cartridge has excellent chemical resistance and maximum chemical compatibility.

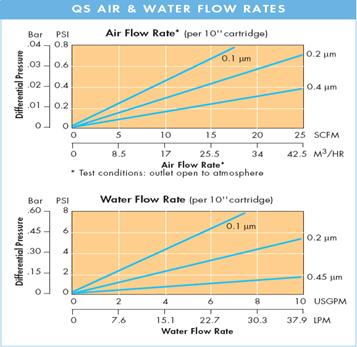

Higher flow rates with lesser pressure drop

Free from binders since end caps are thermally sealed.

Absolute rated

Steam Sterilizable

PRODUCT SPECIFICATIONS :

Micro rating |

0.1, 0.2, 0.45, 1 micron |

Length |

10" , 20", 30", 40” |

Inner Dia |

Approx. 28 mm |

Outer dia |

Approx. 65-69 mm |

Effective Surface |

7.5 Sq ft. (0.65 msq) per |

Max operating temp |

95˚ C (176˚ F) |

Sterilization |

121˚C,30 min, approx 100 times |

Max operating |

Pressure5.5 bar (75psid) @21˚C |

CONSTRUCTION:

Filter media: 100% PTFE membrane

Support media: Polypropylene fiber

MOC: Polypropylene

‘O’ Ring/ Gaskets: Silicone/ EPDM/ Viton

CONFIGURATION:

Double open end type (DOE Type)

Code 7S (226 ‘O’ Ring design/ Bayonet or fin)

Code 3S (222 ‘O’ Ring design/ Bayonet or fin)

APPLICATIONS:

Pharmaceutical industry

Vent filtration

Sterilisation of inlet and exhaust flow

Nitrogen gas filtration

Strong acids and base filtration

Sterile filtration of compressed air

Electronic industy

Cleaning & manufacturing process of semiconductor

Cleaning & manufacturing process in LCD factory